Improvising in Iraq

Published 12:00 am Monday, February 8, 2010

CONTINGENCY OPERATING LOCATION Q-WEST, Iraq — Seen from the gunner’s turret is the Self-Protection Adaptive Roller Kit of a scout truck in 1st Platoon, B Company, 2nd Battalion, 198th Combined Arms, 155th Brigade Combat Team, out of Greenwood. Spc. Michael A. Boucher, the scout truck driver from Batesville, designed, assembled and mounted additional mud flaps atop the left and right roller banks of the SPARKs – a device that absorbs bomb damage, shielding the vehicle and crew. The additional mud

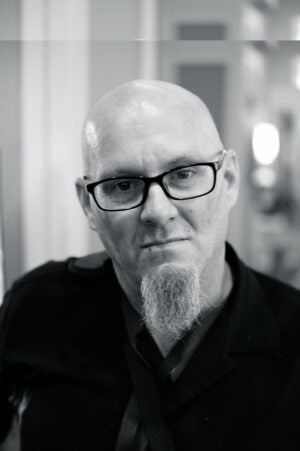

CONTINGENCY OPERATING LOCATION Q-WEST, Iraq — Spc. Michael A. Boucher, the scout truck driver from Batesville, holds a remote control switch he rigged to operate a spotlight he installed in the gun turret of his Mine-Resistant, Ambush-Protected gun truck, in the company motor pool. Feb. 4. Boucher also made additional mud flaps for the Self-Protection Adaptive Roller Kit – attached to the front of the vehicle, absorbing bomb damage and shielding the vehicle and crew – and those flaps have decrea

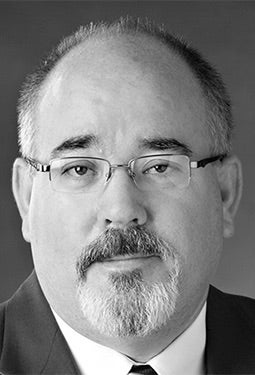

By Capt. Murray Shugars

2nd Battalion, 198th Combined Arms

CONTINGENCY OPERATING LOCATION Q-WEST, Iraq — Winter mud can pose safety and security risks to gun truck crews, but a Mississippi Army National Guard Soldier has come up with a method for minimizing those risks for his scout gun truck.

Spc. Michael A. Boucher, a driver from Batesville, serving with 1st Platoon, B Company, 2nd Battalion, 198th Combined Arms, 155th Brigade Combat Team, out of Greenwood, designed and installed additional mud flaps to the Self-Protection Adaptive Roller Kit attached to the front of the gun truck to absorb bomb damage, shielding the vehicle and crew.

Boucher’s ingenuity has significantly improved the effectiveness, security and safety of his scout vehicle and, therefore, the platoon, said 1st Lt. Nathan W. Hughes, Boucher’s platoon leader.

“Mud is a big problem during rainy season, and the SPARKs kicks mud up onto the (Mine-Resistant, Ambush-Protected) truck, making the situation worse,” said Hughes, also of Batesville. “The windows got muddy, and the scout truck would have to slow down for safety. The scouts would even have to stop every six or eight miles, just to wash the mud off the windows. This slowed the whole convoy and put all the vehicles at greater risk. Specialist Boucher came up with an idea to solve the problem, gained the necessary materials and fixed it on his own. No one told him to do this.”

Staff Sgt. Robert E. Cullom, Boucher’s platoon sergeant, agreed that Boucher’s invention has improved safety and security.

“During the rainy season in Iraq, the thick mud splashes up from the road and covers the windshield and the gun turret,” said Cullom, a resident of Flowood. “We conduct our missions at night, so we always operate in conditions of limited visibility, but the mud makes it a lot worse, and the scouts need to see the roads. If they can’t see the roads, they can’t effectively scout for the convoy. The extra mud flaps Boucher added have made a big improvement on their ability to see the roads.”

Sgt. Edwin L. Pauley, Boucher’s gun truck commander, said that Boucher’s efforts have helped the convoy avoid accidents.

“We can see much better, and the extra mud flaps have definitely decreased our risk of accidents,” said Pauley, a Salisbury, Md., native. “The SPARKs throws mud and stones on the windshield so you can’t see potholes and craters, let alone possible (improvised explosive devices).”

The mud flaps have also improved the ability of the turret gunner to provide security, said Spc. Robert S. Lacey, the gunner.

“Before we started using Boucher’s mud flaps, the SPARKs threw mud and stones all the way up on my turret,” said Lacey, a native of Houston. “Mud covered my blast-resistant windows, my goggles and my weapon and ammunition. That reduced my effectiveness a good deal. For instance, if the truck is near something, I’ve got to be able to look down through my turret windows. Also, if my weapon and ammunition get fouled in mud, the gun could malfunction. Since Boucher made those mud flaps, I haven’t had any issues with mud. It’s easier for me to scan through my windows to where I don’t have to stick my head above them, which puts me at risk.”

Boucher said he spent several weeks finding the materials to build the flaps.

“I used a section of wire mesh from a scrap HESCO barrier to make the curved form,” said Boucher. “I went to the department of public works and got a sheet of quarter-inch rubber, a one-by-four board and mounting bolts.”

Once he collected the necessary materials, Boucher said he spent three days making and mounting the mud flaps.

“It took me so long because I had to cut the HESCO mesh with bolt cutters,” said Boucher. “I cut the rubber flap with the serrated blade of an Army-issued multi-purpose tool.”

Boucher has made other improvements to his MRAP, such as mounting a powerful spotlight on the gun turret, in addition to those mounted on either side of the gun truck, one used by the driver and the other by the truck commander, said Cullom.

“He figured out a way to mount the light without interfering with the rotating turret,” said Cullom. “This has increased the scout truck’s security at night because three sets of eyes can scan with the spotlights. He made a metal plate to mount the light, he rigged the power cable and he figured out a way to mount the remote control panel in the turret.”

Boucher was modest about his accomplishments, saying he enjoyed fixing the problem.

“I like fixing things, and back home, I have a small engine business on the side,” he said. “My dad taught me to work with my hands, fixing cars and go carts, and I’ve always enjoyed that. Anyway, I was just doing what needed to be done,”